Date:2020-03-07 Publisher:

Q1: Is your machine single-head? A two-head machine can strip boxes ranged in opposite directions on a sheet. As a single-head machine, can it achieve the same target?

A1: Our machines, Super Single-Head Waste Strippers, though single-head, are able to strip the waste of boxes ranged in opposite directions in one time, as well as of the boxes with six different sizes and shapes which usually require six-head machines. This is our exclusive and innovative patented invention (ZL2015103048859)!

Q2: Could you tell us about the technical superiority of your machine?

A2: A drawer type mold base and a spinning pin base are innovatively designed. The mold base is able to bear a sheet with two boxes ranged in opposite directions or more boxes of different sizes and shapes, as is shown below. In terms of boxes ranged in opposite directions, the direction of the products can be identified by the translational motion of the upper mold while the spinning of the ejector pins in the lower mold makes it possible to match the box shape in the upper mold, both realized at the same spot. Nevertheless, two-head machines have to complete these two tasks in different spots.

Q3: How long does it take to calibrate the machine for a new product?

A3: It takes about ten minutes.

Q4: What is the output of your machine every 8 hours? Please give us some data.

A4: The output depends on the number of item on each sheet and the quantity of the order. According to the data provided by our client who manufactures medicine packaging boxes, the output during each shift (8 hours) is about 80,000 items (12 to 15 items each sheet). The medicine packaging boxes use 350 GSM paper. The output can be higher in case of 250 GSM paper.

Q5: Our product includes 6 types of boxes with different sizes and shapes (12 items on each paper sheet in size 750x1050mm). Do you have a suitable machine to meet our demand?

A5: Our H-Type machine is the one you need. With its drawer type mold base and programmable intelligent ejector pins, it’s able to adapt to various types of boxes.

Q7: Does your machine have any specific requirements to the perforation of the die?

A7: There are no specific requirements. Of course, the holes should not be too big.

Q8: What should we do if the die-cut paper is not aligned?

A8: One way is to use the paper jogging. Our delivery conveyor is made of double bearing steel, which can align the paper directly by jogging, Otherwise you can use our automatic paper feeder, which is able to align the paper automatically and reduces the wastage of products caused by paper jam.

Q9: Will the top sheet and the bottom sheet of the paper stack move out of place when the delivery conveyor is working? Some of our paper becomes slick and warped after the UV-coating and lamination.

A9: You don’t need to worry about it. Adopting our patented technology (ZL2016102587404), the delivery conveyor on our products can effectively prevent the top sheet and the bottom sheet from moving, which is one of the main features.

Q10: Our paper cups are made by rotary die-cut machines ranged in opposite directions. And the printed sheets have curved edges and no gripping traces. Is your machine suitable for stripping our products?

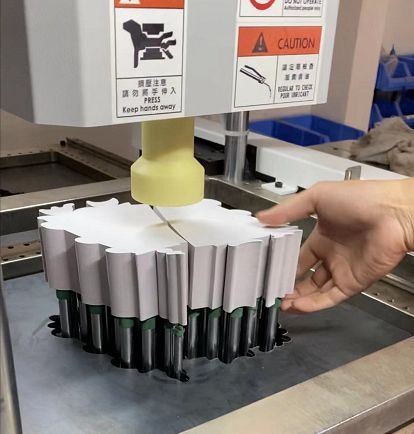

A10: Absolutely. Our machine will be your perfect solution as you can see from the picture below.

Q11: Is your machine applicable to PET sheet boxes with the thickness of 0.25 mm or more?

A11: Absolutely, Many of our clients have already started to use our machines for their PET sheet products, as you can see from the picture below.

Q12: Our company provides post-processing services. Therefore, we have various types of products like tags, medicine packaging boxes and cosmetics boxes, irregular-shape boxes and carton boxes with lock. We use mold-stripping for big orders while it is not worthy for small production like 1000 items. Instead, we use block-press stripping. Do you have a machine that applies to both cases?

A12: Our Model M1050C and H1050C types are applicable both for mold stripping and block-press stripping.

Q13: What is the maximum stripping size of your universal model? Will the ejector pins leave traces on the bottom of carton?

A13: The maximum stripping size of our machine is 400mm * 400mm.However, we also provide customized service for products of bigger size. The tip of our ejector pin is made of German high-elastic cotton which will not leave any traces on the bottom of the carton.

Q14: Does your company provide any training services for the machine operation? Is it difficult to handle? How long does it take to learn it?

A14: Our company provides training services and the machine is easy to use even for elder or women staff. It takes normally about two days to get the hang of it.

Q15: What is the operation platform of the machine made of? Will the white cardboards get stained by the platform?

A15: The platform is made of 15mm thick steel plates with hard chromium plating to prevent stains on white cardboards. This is also our core technology.

Q16: Why are there no air beads on the platform as on paper cutting machines?

A16: The air beads on paper cutting machines aim to reduce the friction between the paper and the platform. However, the air beads cannot take any effects as the air can escape from the space around the paper having been die cut. Moreover, they may bring side effects. Therefore, it is unnecessary to install air beads on the platform of our machine.

Q17: Our company is based in Indonesia. At the moment, there is a particular product (Figure 1) which cannot be stripped by machines but dozens of workers by hand. It has been our main concern. I wonder whether you can customize a machine for this product?

A17: We do provide customized services. Nevertheless, all models of our machines are applicable to this product (Figure 2) so it is unnecessary to customize.

Figure 1

Figure 2

Q 18: Compared to the double-head machine, what is the advantage of your Super Single-Head (SSH) machine?

A18: It is a common layout to have two boxes ranged in opposite directions during the printing imposition to save paper. Double-head machine is designed to deal with this case since the single-head machine can only strip paper ranged in the same direction. The SSH machine is superior in the following aspects. Firstly, it takes only about 10 minutes to calibrate our SSH machine, half of the time needed for double-head machines because calibrating a double-head machine is similar to adjusting two single-head machines. Secondly, according to the mechanical drive principles, the shorter the transmission distance is, the higher the accuracy will be. The transmission distance of double-head machines is double of the single-head machines leading to lower accuracy. Thirdly, our SSH machine is smaller than a double-head machine and occupies less space. which means lower rental cost from the user.

Q19:What economic benefits will your waste stripping machine bring to us printers?

A19:The output of our machine each 8 hours is about 80,000 items (15 items per sheet). Considering the manual processing fee for 10,000 items of boxes (15 items per sheet) is 200 yuan, 80,000 items cost 8*200=1600 yuan. In terms of die cutting machine, the processing fee is 0.03 yuan for each item of paper. Its output is about 45000 items each 8 hours, which cost 45000*0.03=1350 yuan in total. It can be clearly seen from the figures the value of our products.

Q20:Why does your machine cost much more than those from other companies?

A20:It’s important to note that the performance and efficiency of the other products are not comparable to ours. We have invested a lot in innovation so that our machines are equipped with many patented technologies to ensure an outstand performance and high efficiency. Our investment includes the following aspects---

1. The research and development at the design phase and the maintenance for the patents

2. The fine materials and finishing used for the machine

3. High-quality parts such as pneumatic components, wire rod guide and etc.--- Cost can be more than 10 times different for different quality products.

4. The selection of electrical components (For example, a high quality motor costs more than 5 times than an average one);

5. 5. The hydraulic system--- cost can be more than 10 times different for different quality products.

6. 6. The operating system--- our operation system is easy and stable with little chances of crash or breakdown.